Key Advantages Of Barrier Technology In Healthcare And Allied Industry

The healthcare industry is thriving like never before. This is because of the advances that are being made in the technologies and devices that are frequently used in pharmaceutical companies, clinical research laboratories and hospital setups. A key requirement of the healthcare sector is to be able to maintain sterility at designated sections. This is extremely important for pharmaceutical companies where aseptic handling of medicines is required, clinical trials where aseptic mixing of reagents is a must, and hospitals where hormonal and chemo preparations are compounded and dispensed.

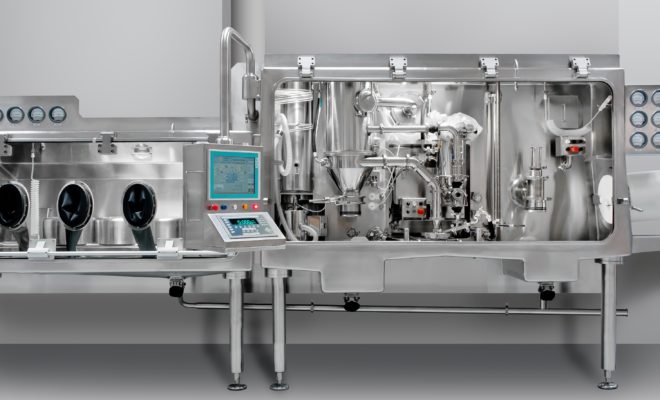

Most of these practices rely on turnkey barrier isolator systems and Restricted Access Barrier Systems (RABS) along with clean air microsystems that allow generation and maintenance of sterile workplaces. Because of the advances made in designing and engineering these systems, it has been possible to make this process hassle-free and more efficient. Creating and maintaining sterility is of extreme importance in healthcare and allied industries and offers the following advantages:

Better maintenance and upkeep of sterile rooms

Barrier technology has led to significant ease of creating, managing and upkeeping sterile units and workplaces. Barrier isolator systems, for example, allow preparation of a sterile room with great ease and this is indeed very useful for formulation of pharmaceutical preparations like injectables and eye drops. This technology has led to a significant cost reduction in the manufacturing, processing and packaging of these medicinal agents. These systems have also made it easy for the company to manage and upkeep these areas.

Easier and faster sterilisation of equipment

Only because of technological advancements like turnkey barrier isolator systems medical and clinical equipment can be sterilised properly and promptly. These systems ensure that contamination levels are drastically reduced and managed better. Not only the equipment, but entire workspace can be thoroughly sanitised so that handling of sterile equipment is easier and more effective.

Improvements in patient safety

Patient safety is the crux of healthcare and allied industries. If the safety of the patient cannot be guaranteed in any medical procedure or treatment line, the whole healthcare sector will have to face grave consequences. Tremendous advancements have been made in patient safety processes and many of them are a direct implication of barrier technology. The danger of contaminated medicinal preparations and equipment has been contained to a great extent since the introduction of barrier systems because drugs can be handled in sterile microenvironments and processed aseptically. The same holds true for devices and equipment.

Overall reduction of costs

Thanks to modern sterility technologies like turnkey barrier isolator systems, the incidences of microbial contamination have gone down drastically. This automatically translates into much lesser expenditure on contamination control processes, decontamination testing and follow up processes. Consequently, the overall costs go down tremendously.

Maintaining sterility is of utmost importance in healthcare and allied industries like pharmaceutical sector and clinical research. Noteworthy advances in this regard have been made possible because of barrier technology. The inclusion of this technology in hospital setups, clinical research laboratories and pharmaceutical plants have brought about many positive changes.